Surfing is part of Noah’s DNA, and this spring, we’re proud to introduce a collection of custom-shaped surfboards with signature graphics, sunscreen, a branded surf leash, and organic surf wax, all of which have been made in the USA.

MATUNAS WAX FARM IN SANTA CRUZ, CA

MATUNAS WAX FARM IN SANTA CRUZ, CA

If you surf, it’s not news that so much of the equipment available, and that you see being used, is made overseas. We wanted to focus, instead, on the expert craftsmanship available from US companies who’ve chosen to keep production here.

They’re all run by surfers: Jordan Brazie of Valaric (the boards), Craig Ephraim of XM | Surf More (the leashes) and Matthew Matoon of Matunas (the wax). We had a chance to ask all 3 about their businesses, and what it means to them to produce their products in America. What follows is a collection of their answers to some of our questions.

Tell us about your companies and what you do.

Jordan Brazie: I shape at Wave Riding Vehicles full-time, and my personal label (and side hustle) is Valaric. I make surfboard shapes of all calibers, built with high quality and intention, and I’m based in Virginia Beach.

Craig Ephraim: Bob Nealy started XM | Surf More in 1973, after seeing a need for a Velcro surf leash. I’d known Bob from down at San Onofre (in San Diego county, CA) for a number of years, and he offered me a job in July of 1981 basically tying leashes. I became the manager in 1984, and I’m still making leashes.

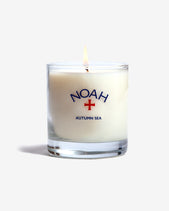

Matthew Mattoon: Matunas is based in Santa Cruz, CA. We make organic surf wax, ski wax, skate wax, cosmetics, candles, and lip balm. We also just launched a children’s book, Gogo, as we’re planning on coming out with more children’s products.

Any previous experience or jobs that led you down this path?

Jordan Brazie: Prior to working with WRV, I made it a mission to learn from elders of the trade. I ghost-shaped for a couple shapers, and hovered over the shoulders of others. Virginia Beach has a long history of world-class shapers dating back over 6 decades. These relationships grew my knowledge of the diverse designs and theories that became the foundation of my work.

Craig Ephraim: No. Other than I surfed and knew Bob.

Matthew Mattoon: Back in 1995, I wanted to create a surf wax that was just as organic as the organic produce supermarkets carried. Growing up in a farming family and having access to growing organic food was also a catalyst for this venture.

What does it mean to you personally to offer a Made in the USA product?

Jordan Brazie: I believe in supporting my community first. Fair labor and locally-made products enhance the quality of life and increase opportunities where I live. I want my city’s economy to be successful, and, ideally, self-sufficient.

Craig Ephraim: When I started here, everything was made in the USA and/or Australia. Almost all other leash companies shifted over to China in the early 2000's. Although some components are imported (because they’re no longer made in the US) we still pride ourselves on keeping the innovation and production here.

Matthew Mattoon: That all the ingredients come from the US, and the entire product is produced in the US only.

JORDAN BRAZIE AT VALARIC, VIRGINIA BEACH

JORDAN BRAZIE AT VALARIC, VIRGINIA BEACH

What are the pros & cons of having a business in the USA?

Jordan Brazie: I would say the main pro is maintaining quality, which is key to growing a business in surfboard production. Having an accountable team, along with a facility that’s within an arm's reach, keeps us fluid and adaptable.

Craig Ephraim: The main issues are the costs. Materials, labor, taxes, rent, regulations, permits, etc. The pros are being able to guarantee the best quality leashes, and knowing that Americans are employed instead of people in sweatshops.

Matthew Mattoon: The pros are having access to such wonderful resources. The cons have been that workers don’t always show up on time, but I think that can happen anywhere.

Are any components of your product sustainable?

Jordan Brazie: Building boards to last longer than ever before without compromising function is an ever-growing goal of mine. I’m always trying to expand greener options for my customers through recycled and earth-friendlier materials. The US facility that’s the main source of our blanks is 100% solar-powered.

Craig Ephraim: Because we use the best quality components and manufacturing processes our products typically have a much longer life which means less leashes being thrown away and creating more waste. I believe we're the only leash company in the world to sell every part of a leash separately which makes it easy and affordable to repair, reuse, and replace any parts you need.

Matthew Mattoon: We use only organic, sustainable materials for all our goods.

XM | SURF MORE FACTORY IN SAN CLEMENTE, CA

XM | SURF MORE FACTORY IN SAN CLEMENTE, CA

How do you stay competitive in the surf world which offshores many of its products for manufacturing?

Jordan Brazie: Beyond the support of those who consciously buy US-made products, most of my repeat business is from people who appreciate a direct line of communication and seek out a guaranteed premium product.

Craig Ephraim: It's almost impossible costs-wise. But again, the quality is unbeatable.

Matthew Mattoon: Offering organic products without compromising the quality for the past two decades has made consumers rely on what we make and use their purchasing power to get behind our brand.